FPGA-Based Functional Safety for Industrial Applications: Functional safety is of the utmost importance in industrial applications, where system failures can have severe consequences such as injury, loss of life, or environmental damage.

To ensure functional safety, industrial systems must be designed to detect and prevent hazardous situations, as well as minimize the likelihood of failure.

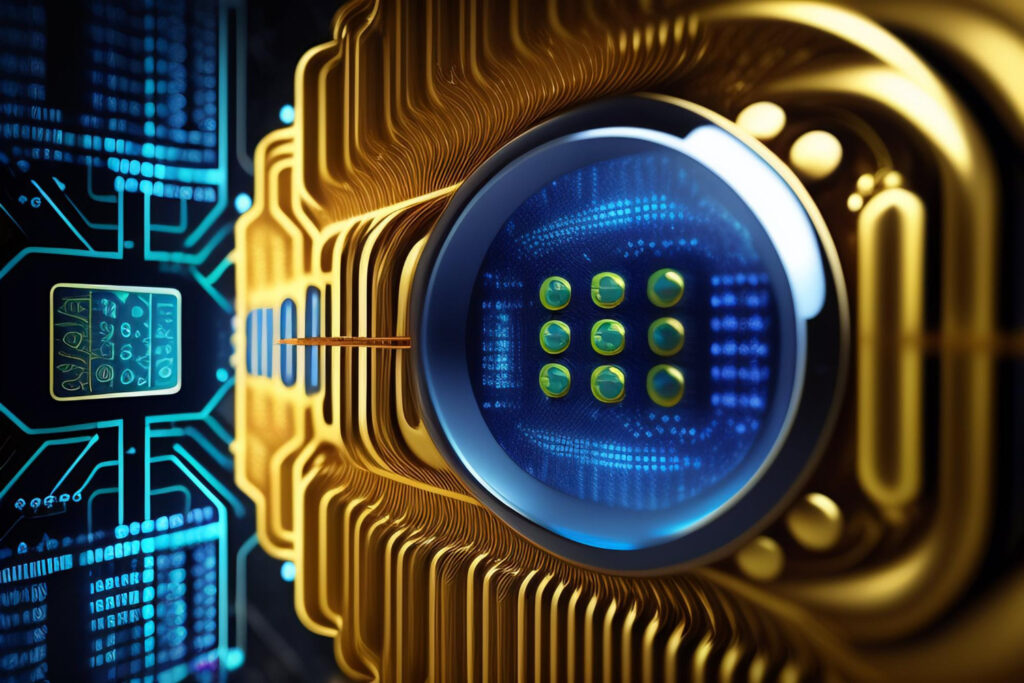

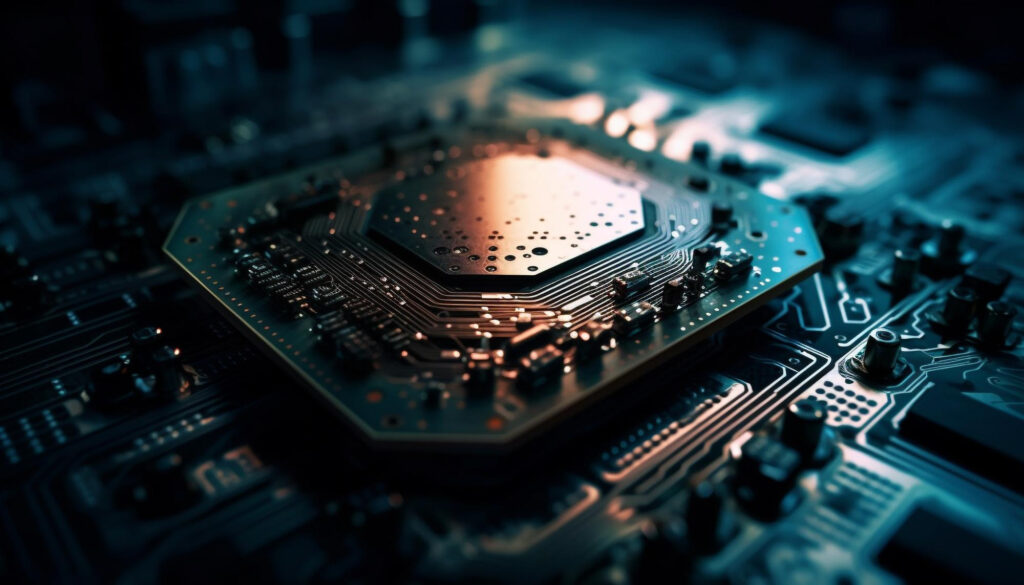

Field-Programmable Gate Arrays (FPGAs) are programmable logic devices that offer significant advantages in implementing complex digital systems for industrial applications.

They provide exceptional performance, flexibility, and reliability, making them an ideal choice in various industries.

Moreover, FPGAs can be programmed to incorporate safety features like monitoring and control, which play a critical role in achieving functional safety.

In this blog post, we will explore the benefits and advantages of utilizing FPGA-based functional safety in industrial applications.

We will delve into how FPGAs enable the development of robust and secure systems that are capable of identifying and mitigating potential risks, thereby ensuring a safer working environment.

Benefits of FPGA-Based Functional Safety

FPGA-based functional safety offers several key benefits in industrial applications. Here are some of the advantages:

Performance

Performance

- The high-performance capabilities of FPGAs are well recognized. They can handle data at breakneck speeds and effectively carry out complicated algorithms.

- Because of this, they are appropriate for real-time applications that need speedy responses, including safety-critical systems.

- FPGAs can help industrial applications reach the performance levels required to promptly detect and react to dangerous situations.

Flexibility

Flexibility

- FPGAs offer a lot of design flexibility for systems. These devices are adaptable to changing industrial requirements since they may be reprogrammed and modified as necessary.

- FPGAs allow for the implementation of safety measures that are specialized to meet the needs of certain applications in the framework of functional safety.

- Due to its adaptability, safety features can be upgraded or changed as needed without requiring large hardware changes.

Reliability

Reliability

- Systems must be dependable and strong in industrial environments. The inherent hardware redundancy and fault tolerance properties of FPGAs are what give them their reputation for dependability.

- As a result of their ability to contain multiple components, these devices can be equipped with security features including hardware-based error detection and redundancy management.

- The ability to self-diagnose and detect faults can also be built into FPGA designs, allowing for dependable operation and constant monitoring.

Integration

Integration

- FPGAs have strong integration capabilities that make it possible to combine several functions into a single device. Due to the removal of extra components, the system becomes simpler and has fewer possible weak points.

- Industrial applications can achieve higher levels of system integrity and lower the chance of mistakes or failures due to inter-component communication by integrating safety-critical operations into an FPGA.

Verification and Validation

Verification and Validation

- Functional safety standards frequently call for exacting validation and verification procedures. By enabling designers to simulate and evaluate safety features in a virtual environment, FPGAs make this process simpler.

- The support for cutting-edge modeling and testing procedures provided by these devices enables complete validation of safety systems before deployment.

- This capability increases trust in the system’s functional safety and aids in ensuring compliance with safety regulations.

Long-Term Support

Long-Term Support

- Manufacturers often provide FPGAs with long-term availability and support. For industrial applications that demand dependable, long-term functioning, this is crucial.

- Industrial systems can be constructed with confidence knowing that the necessary components will be readily available for a long time if supply and support are solid.

Examples of FPGA-Based Functional Safety

FPGA-based functional safety is utilized in various industrial applications to enhance safety measures and ensure reliable operation. Here are a few examples of how FPGAs are employed in functional safety systems:

Automotive Industry

- FPGAs are used in the automobile industry to enable functional safety in advanced driver assistance systems (ADAS) and driverless vehicles. FPGAs are essential for processing sensor data, implementing safety-critical algorithms, and facilitating quick decisions for adaptive cruise control, lane maintenance, and collision avoidance.

- They offer the efficiency, adaptability, and real-time capabilities required to assure the secure and dependable functioning of these systems.

Examples:

- Anti-lock Braking System (ABS): Real-time monitoring and management of the ABS can be implemented using FPGAs, guaranteeing that the braking system reacts precisely and dependably to avoid wheel lock-up during abrupt braking.

- Advanced Driver Assistance Systems (ADAS): For quick data processing, sensor fusion, and real-time decision-making, FPGAs can be used in ADAS applications like collision avoidance systems, adaptive cruise control, and lane departure warning systems.

Industrial Control Systems

- Industrial control systems that require functional safety frequently employ FPGAs. These systems include safety instrumented systems (SIS), distributed control systems (DCS), and programmable logic controllers (PLCs).

- FPGAs are used for real-time monitoring, control, and safety tasks such as safety interlocks, emergency shutdown mechanisms, and fault detection and diagnostics.

- FPGAs’ adaptability enables the modification and adaptation of safety elements following particular industry requirements.

Examples:

- Programmable Logic Controllers (PLCs): FPGAs can be integrated into PLCs to offer important industrial processes with high-speed I/O processing, precise timing control, and fault detection capabilities.

- Safety Instrumented Systems (SIS): To ensure safe shutdowns and avoid dangerous circumstances, SIS can employ FPGAs to monitor and manage safety-critical functions in sectors including oil and gas, chemical processing, and power generation.

Aerospace and Defense

- FPGAs are used in safety-critical systems, including avionics, flight control systems, and missile guidance systems, in the aerospace and defense industries. Real-time processing, rapid data transmission, and fault tolerance are made possible with FPGAs, enabling dependable and secure operation.

- To ensure the secure operation of these systems, they are essential in putting safety measures like failure detection, redundancy management, and fault-tolerant control into place.

Examples:

Flight Control Systems: To interpret sensor data quickly, regulate actuators precisely, and operate fault-tolerantly during crucial flight maneuvers, flight control systems can make use of FPGAs.

Radar Systems: For target detection, tracking, and data processing in radar systems, FPGAs can be used, giving operators real-time situational awareness and enhancing system performance.

Medical Devices

- FPGAs are used in medical devices because functional safety is a top priority. FPGAs are used for real-time data processing, signal analysis, and other safety-critical tasks in devices including diagnostic equipment, imaging systems, and patient monitoring systems.

- To assure patient safety and the dependable operation of various medical equipment, FPGAs enable precise control, accurate data processing, and the application of safety features.

Examples:

MRI and CT Scanners: To handle real-time image processing duties, data collecting, and control operations, FPGAs can be integrated into medical imaging devices, resulting in accurate and timely diagnostics.

MRI and CT Scanners: To handle real-time image processing duties, data collecting, and control operations, FPGAs can be integrated into medical imaging devices, resulting in accurate and timely diagnostics.

Implantable Devices: FPGAs are capable of delivering precise and dependable therapy, adjusting to changing patient conditions, and responding to safety-critical events in implantable medical devices like pacemakers or neurostimulators.

Energy and Power Systems

- Functional safety systems are implemented using FPGAs in the energy and electricity industries. They work on electricity distribution networks, smart grid infrastructure, and control systems for power plants.

- For dependable power distribution, fault management, and emergency shutdowns, FPGAs provide monitoring, fault detection, and safety measures.

- They offer the performance and flexibility required to manage the complexity of these vital energy networks.

Examples:

Smart Grids: FPGAs can be used in smart grid systems to enable real-time monitoring, control, and optimization of power distribution as well as problem detection and quick reaction to ensure a dependable and secure power supply.

High-Voltage Converters: FPGAs can be used to control power conversion, fault protection, and grid synchronization in high-voltage converters for renewable energy systems or electric vehicle charging stations.

These illustrations show how functional safety measures are implemented in several sectors using FPGAs.

In sophisticated and safety-critical industrial applications, FPGAs provide the customization, real-time capabilities, and reliability required to accomplish functional safety goals.

FPGA in functional safety Applications

For creating a secure architecture, the flexibility of FPGA offers a wide range of architectural and implementation possibilities.

Additionally, it enables the adoption of intelligent designs, which aid in minimizing the requirement for redundant design approaches employed in the past and minimizing common cause failures.

Only the building blocks required to achieve certification for the particular end system can be employed in an FPGA design.

A design that uses only fundamental building blocks is more effective and uses the FPGA fabric’s resources as needed for each specific Automotive Safety Integrity Level (ASIL).

Developing the safety concept, determining the ASIL level through risk assessment, and identifying the Safety analysis needed for the desired ASIL level are all parts of a typical safety process for automotive applications, backed by appropriate Safety management systems.

Functional Safety With FPGAs

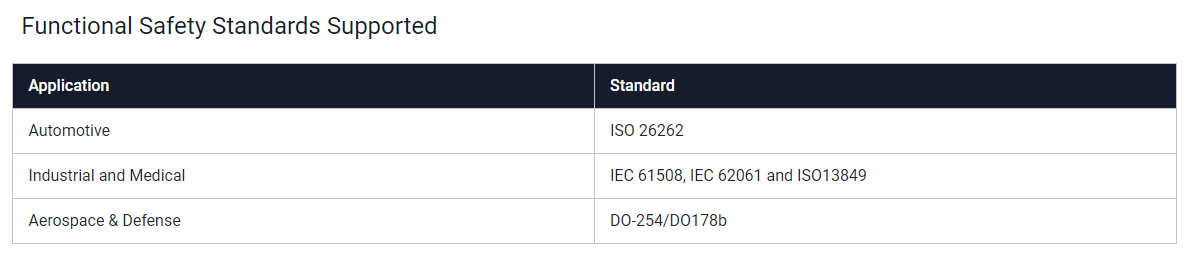

Application of ISO 26262 on FPGA

The creation of an automotive design using FPGAs that satisfies all the requirements of ISO 26262 might be very difficult. Using FPGAs in safety-critical applications presents several difficulties that designers must solve.

- Standardized procedures and templates that adhere to ISO 26262 specifications

- The availability of IP that is ISO 26262-certified and usable in designs

- The availability of tools that can be used to create designs based on ISO 26262

- Segmenting the design to incorporate the standard’s hardware and software requirements

- Choosing tools that are suitable, safe, and provide unique error injection and error detection techniques as required by the standard

Safety Analysis Approach

The main safety operations that take place during a product’s conception, development, manufacture, operation, servicing, and decommissioning phases are covered by the ISO 26262 safety lifecycle.

Managing a project with safety goals required by the ISO 26262 standard depends on planning, organizing, and documenting the safety actions of all safety life cycle phases.

The graphic below shows an example of a safety lifecycle and the associated safety actions.

ISO 26262 Compliant FPGA Development Flow

Critical safety analysis stages are included in the design phase of a safety lifecycle in addition to the typical design flow.

By incorporating safety features into the design and confirming that the ISO 26262 standard is being followed, these assessments are helpful.

The techniques for safety analysis include both qualitative and quantitative methods. The components 4, 5, and 6 of the standard that makes up this analysis—which also includes the FMEA, FMEDA, and FTA—are explained below.

Growth of the Functional Safety Market

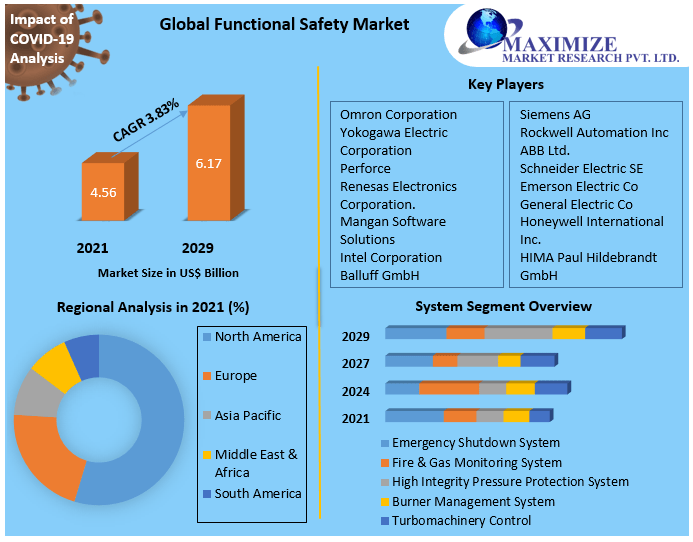

According to maximize market research, the Functional Safety Market size was valued at US$ 4.56 Bn. in 2021 and the total revenue is expected to grow at 3.83 % from 2022 to 2029, reaching nearly US$ 6.17 Bn.

Conclusion

In conclusion, functional safety based on FPGAs has several benefits for industrial applications. For effective safety measures, FPGAs offer the performance, flexibility, and dependability needed.

They offer long-term support, conform with safety regulations, and streamline verification processes. Even though there are difficulties, new trends including safety-certified platforms, fortified features, and AI acceleration help to improve FPGA-based functional safety.

Industry can reach improved levels of safety, preventing dangers and fostering secure working conditions, by utilizing FPGA technology.

![Advanced Driver Assistance System [ADAS] Everything You Needs to Know](https://www.logic-fruit.com/wp-content/uploads/2022/10/Advanced-driver-assistance-systems-Thumbnail.jpg)