Introduction

Measurement Computing offers a variety of applications and interfaces for its data acquisition systems. MCC provides high-quality hardware with corresponding software and drivers for a quick and adaptable data acquisition solution for your particular application, whether you monitor current, voltage, temperature, strain, or digital signals. To sound more professional in the internet-dominated world, you must work with data acquisition systems or DAQ.

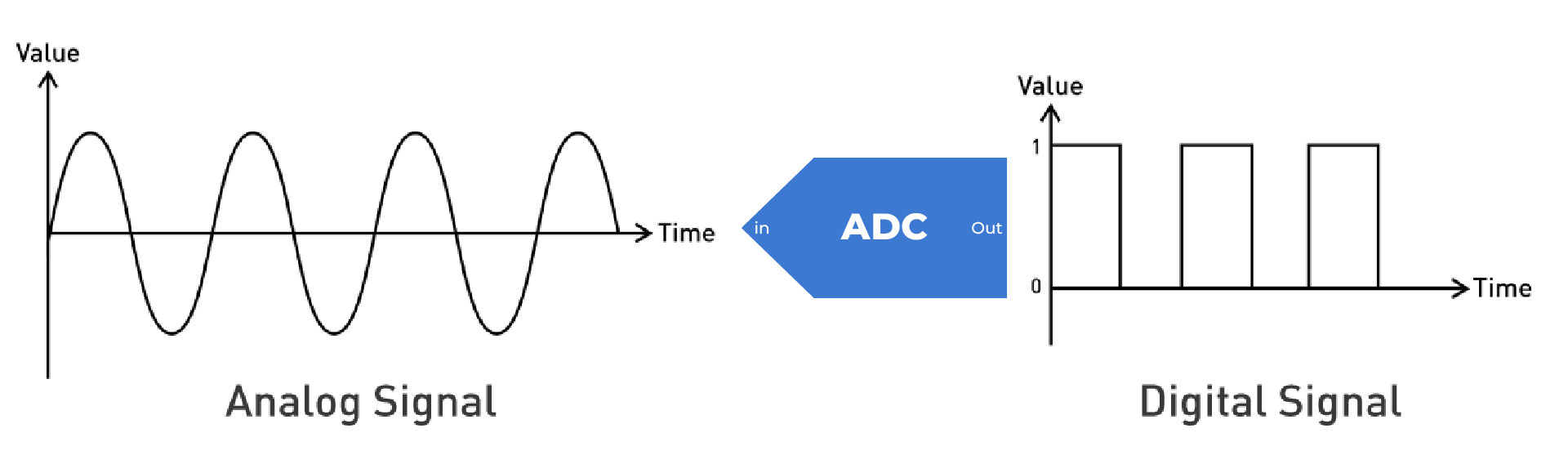

Data Acquisition (DAQ) is sampling real-world signals to digital for computer processing. Unlike tape or paper, it’s digital and manipulatable by software.

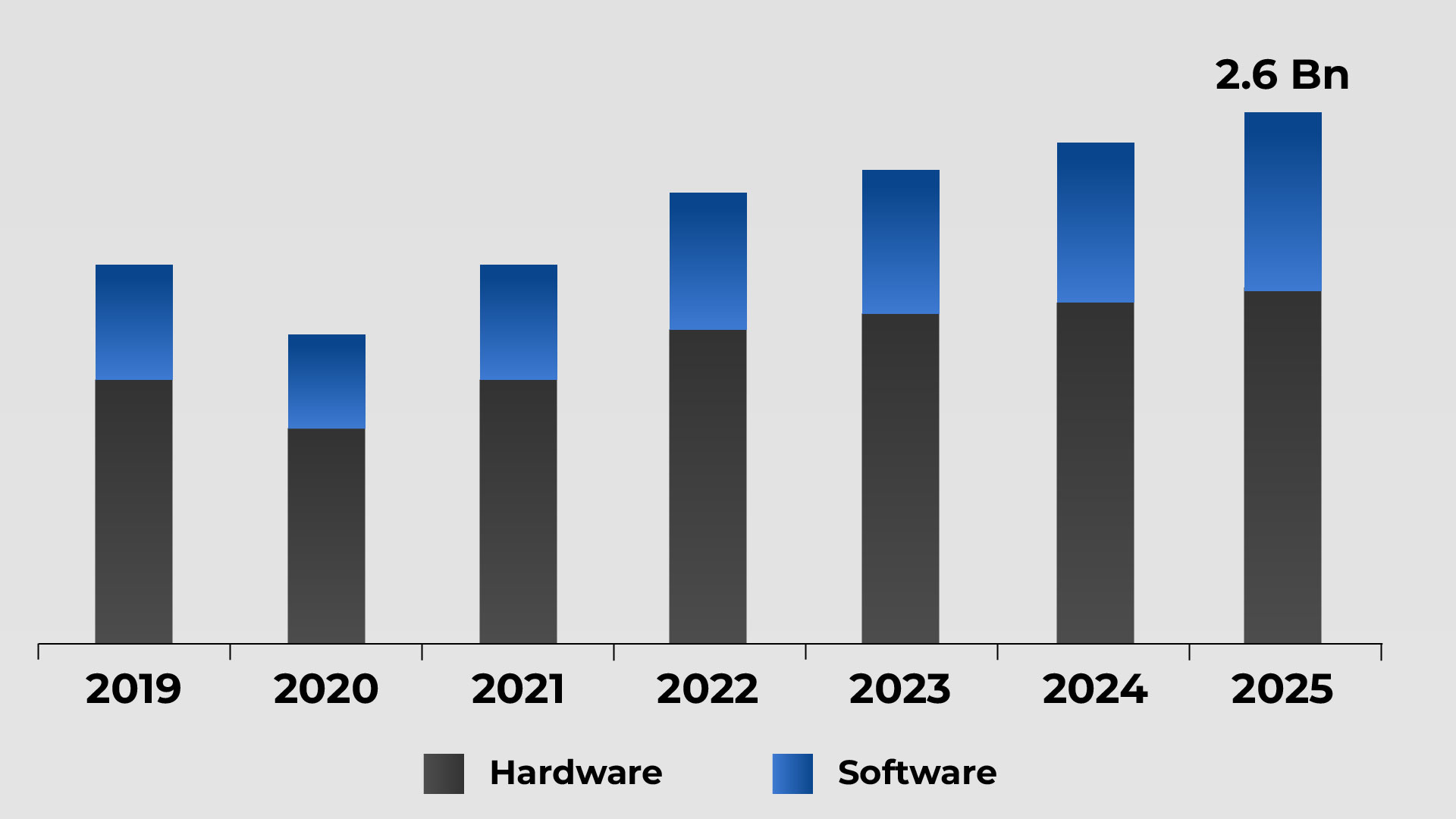

A data acquisition system (DAQ) is anything that records data so you may access observations on other devices. A DAQ performs best while simultaneously keeping track of data using one or multiple devices. Let’s investigate. By 2025, it is anticipated that the global market for data acquisition systems (DAQ) will be worth $2.6 billion, growing at a 5.8% CAGR.

The popularity of business data collection systems in the modern world is influenced by increasing industrial automation and demand for real-time data processing. Gathering data involves using equipment to monitor electrical and physical processes and recording the results on a computer.

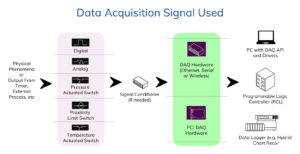

The hardware components of the data collecting system include sensors and a programmable software computer. The DAQ’s hardware component provides an interface between the signal and the PC.

Data gathered by DAQ systems are transmitted to a central monitoring and control facility location via instruments and sensors attached to equipment at multiple industrial sites.

What is a DAQ system?

Data Acquisition, also known as DAQ or DAS, is the method of sampling signals to measure real-world physical events and converting them into a digital format. This digital data can be processed by a computer and software. Unlike traditional methods like tape recorders or paper charts, where signals are recorded in analog form, DAQ converts signals into digital form for storage on ROM, flash media, or hard disk drives. It’s a way of capturing and processing real-world data using computers.

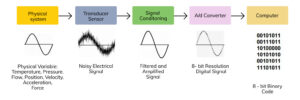

The process of gathering signals that quantify physical situations as they exist in the real world and transforming them into digital numeric values that a computer can analyze is known as data acquisition. Analog waveforms are usually converted into digital values for processing by data acquisition systems, sometimes known by their acronyms DAS, DAQ, or DAU.

A computer, sensors, measurement devices, and data-gathering software are all components of a data acquisition system. To gather, store, visualize, and process data, a data collection system is employed. To comprehend electrical or physical phenomena, information must be gathered.

Systems for acquiring data come in several varieties. It might be a small handheld device for basic temperature readings or a large multi-thousand channel system that is put in multiple racks and controlled remotely.

Software built-in general-purpose programming languages like Assembly, BASIC, C, C++, C#, Fortran, Java, LabVIEW, Lisp, Pascal, etc. are typically in charge of controlling data acquisition applications. Data loggers are a common term for stand-alone data collecting systems.

Additionally, open-source software packages are available that include all the tools required to collect data from various hardware devices, most of which are specialized. These technologies originate from the scientific world, where quick, adaptive, and flexible software is needed for complex experiments.

The First Data Acquisition Systems

In the early 1960s, the American computer company IBM created machines to store scientific data. The IBM 7700 Data Acquisition System and its successor, the IBM 1800 Data Acquisition and Control System, catalyzed this.

IBM 7700 Data Acquisition System

IBM 1800 Data Acquisition and Control System

These systems were large-scale, expensive computers that needed extensive programming and setup to function correctly because they were created well before the personal computer (PC).

However, they did represent a significant advancement in data recording and were a direct precursor to today’s PC-based data capture systems.

Due to their size, scale, and expense, these IBM data gathering systems were primarily utilized by governments and substantial government contractors, such as NASA and various military branches and contractors.

The First PC-based Data Acquisition

The American company National Instruments Corporation began providing fundamental parts for low-cost personal computers in the middle of the 1980s, including analog-to-digital converter boards (DAQ boards) and GPIB data acquisition cards.

The essential element of this system, aside from the crucial innovation of employing a PC as a data collecting platform, was a piece of software called LabVIEW, which was made available in 1986 for the Macintosh personal computer platform.

Engineers might create their data acquisition systems (DAQ systems) using LabVIEW, which comes with an extensive range of built-in features for data processing, analysis, and real-time display on the computer’s monitor.

LabVIEW DAQ software was published 1989 as Lab Windows/CVI, a DOS-based IBM PC version, to cater to most of the PC market.

When Microsoft created its Windows graphical operating system, the ICM PC platform suddenly gained more graphical capabilities than the Macintosh platform.

LabVIEW for Windows PCs was first made available by National Instruments in 1992 and has remained compatible ever since.

The 1990s saw the widespread arrival of personal computers, which completely changed the way DAQ systems were utilized and created. These new PCs made DAQ systems easier to use and more affordable.

In the 2000s, the DAQ system effectively carried on with the arrival of cloud computing and wireless data transfer. These two recent developments open up new possibilities for applications in fields including environmental monitoring, transportation, and healthcare since they enable real-time data collection and analysis from remote places.

As new technologies like artificial intelligence and machine learning are integrated into these systems, DAQ is currently developing. These advancements are expected to increase the application of DAQ systems and increase their potential as a tool for data collecting and analysis.

Data Acquisition Systems Measurements, Modules & Methods

Data Acquisition Systems Measurements

A wide range of measurements can be made with data acquisition equipment. In most cases, analog signals are used to generate these kinds of measurements. They need to be in a digital format before being transferred into any computer system.

A data acquisition system can measure a wide range of parameters, such as the following:

Current

Voltage

Strain

Frequency or time interval

Pressure

Temperature

Distance

Vibration

Angles

Digital signals

Weight

Different modules or sensors can be used to measure distinct parameters, while several general-purpose, multi-input data-gathering devices can interface with these diverse sensors.

Because voltage readings can be translated into measures of temperature, displacement, or any other subject under study, the types of sensors used in data acquisition measurements typically yield voltage values.

A transducer of some type is frequently used by a data acquisition module and a sensor to provide a basic measurement parameter, such as voltage.

The primary measurement is the name given to this measurement. Then, if necessary, it will be transformed into the following parameters.

Data collection modules can measure nearly every necessary parameter that needs to be made or obtained in this way.

Because of this, the enormous variety of DAQ modules available can measure nearly anything. They can also fulfill extremely particular needs.

On the other hand, sensor designs that call for unique DAS modules are also available.

These data-gathering modules can be tailored in this way to use particular sensors for particular measures.

Data Acquisition Cards and Modules

Numerous rack modules found in data-gathering systems are stocked with cards that provide the various measuring capabilities required.

These cards have to be compliant with the overall system used in mechanical and electrical interfaces.

The modules utilized are frequently available from multiple vendors and the rack systems utilized are frequently standardized, making the selection process easier.

Data Acquisition Software

There is specialized data acquisition software available that is needed to gather, store, and process data in a logical manner.

Data acquisition system software can be built in a variety of languages and with a particular use in mind. Alternatively, one might make use of the several accessible data-collecting software packages.

Proprietary data-gathering software packages provide the advantage that most issues have already been solved because all development and system deployment has already taken place.

Although there is a fee associated with software maintenance, it will be far less than if maintenance were attempted on an analogous in-house data-collecting software program.

As a result, the majority of businesses decide to purchase data collection tools, which they then employ to create tests tailored to their specific needs.

Data Acquisition Transducer Signals

Transducers are electrical devices that convert energy from one source into another. The output signal changes based on the particular variable that the DAQ device is intended to measure.

In most discussions, the output signal generated by data-gathering systems is the focus of discussion. Analog or digital output signals can be produced.

Data Acquisition Methods Used by DAQ Systems

Some of the data acquisition techniques include:

Bit-Stream Disk-to-Image File

In certain extremely specialized data acquisition systems, this technique of data acquisition is employed. The majority of people who use this strategy are forensic investigators.

It’s a versatile data capture technique that lets you make one or more copies of the original disk.

More significantly, it replicates every bit of the original drive including linked sectors and clusters to recover files that were later erased or altered.

A few well-liked programs for reading disk-to-image files are ILook Investigator, FTK, X-Ways, EnCase, etc.

Bit-Stream Disk-to-Disk

Alternatively, a bit-stream disk-to-disk approach is employed when software, hardware, or other incompatibilities prevent the production of a bit-stream disk-to-image file.

Investigators make a bit-stream disk-to-disk replica of the original drive or disk when they encounter the aforementioned problems when attempting to obtain data from older devices.

EnCase, SafeBack, and Norton Ghost are the programs used to make the disk-to-disk bit-stream copy of the original tampered drive.

With the use of these tools, the shape of the destination disk can be changed to match the data that was transferred from the original suspect drive.

Logical Acquisition

Only the files necessary for a specific case inquiry are gathered using this strategy. This process might be used, for instance, to gather Outlook. ost or.pst files for email investigations and to get particular records from a sizable RAID server.

Sparse Acquisition

This approach is comparable to logical learning. Investigators can get tidbits of unallocated data using this way. This approach is typically taken when a complete driving inspection is not required.

Components of a DAQ system

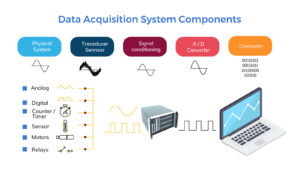

In the process of gathering data, the physical occurrences or attributes that need to be measured come first.

Factors such as temperature, force, fluid movement, light intensity, vibration, gas pressure, and vibration are frequently taken into account in a DAQ system.

Before measuring any kind of physical characteristic, the physical state needs to be unified into a form that can be sampled by a data-gathering system.

Sensors are responsible for these changes. A data acquisition system is a collection of hardware and software components that makes it possible to measure or manipulate the physical characteristics of real-world objects.

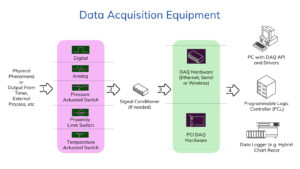

DAQ hardware, sensors, actuators, signal conditioning equipment, and a computer running DAQ software make up a complete data acquisition system.

Sensors (Transducers)

All the Real-world phenomena like temperature, force, movement, and many more parameters are continuously changing in nature. The measurable quantities that represent the characteristics of any system in nature are called Variables.

The proper functioning of a particular system depends on certain events in time and the parameters of these variables. These variables must be measured with a device that converts the phenomena into a form that humans can perceive.

The conversion devices that translate these physical phenomena into electrical signals (or vice-versa) are called Sensors or Transducers.

Standard sensors include old Mercury Thermometer to Thermocouples, Thermistors, RTDs for measuring Temperature, Load cells for measuring weight and load, Strain gauges for strain on an object (force, pressure, tension…), Microphones for measuring sound, Accelerometers for vibration and shock, and many more.

It’s crucial to consider aspects like the sensor’s accuracy, stability, and behavior in different environmental conditions.

The signal conditioning is necessary to capture a reliable signal when selecting the appropriate sensor for the measurement system.

Signal Conditioning

Additional circuitry is frequently required between the transducer and the ADC to perform high-quality measurements on transducers.

Amplification/attenuation, filtering, Wheatstone bridge completion, excitation, linearization, calibration, and cold-junction compensation (CJC) are some of the circuitry types that can be included in this signal conditioning circuitry.

Different sensors require various types of signal processing. For instance, excitation, bridge completion, and calibration are necessary for signal conditioning for a strain gauge. Before passing through the ADC, the signals from thermocouples, which produce signals in the mV range, must be amplified and filtered.

Signal conditioning circuitry can sometimes be found inside a data-gathering device, but it can also be found inside a transducer. For instance, load cells have amplification, calibration, and bridge completion circuitry.

In addition to signal conditioning, many MEM (micro-electro-mechanical) sensors have it.

Analog-to-Digital Converter

An Analog to digital converter is the foundation of every data-gathering system (ADC). As the name suggests, this chip transforms analog electrical data into discrete levels that processors can understand.

The slightest change in the detected signal that can be detected corresponds to these distinct levels. The more discrete levels used to represent an analog signal and the larger the number of “bits” (12-bit, 16-bit, 24-bit, etc.) of an ADC, the better the ADC’s resolution.

An ADC’s resolution can be compared to a measuring stick’s ticks in many ways. The resolution of a measuring stick with mm tick marks is more significant than one with simple cm tick marks.

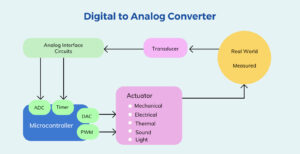

Digital-to-Analog Converters

Supporting both the input and output of binary signals is the purpose of this DAQ system component.

Computer with DAQ software (Storage and Display)

Computer with DAQ software (Storage and Display)

The converted variables can be observed in real-time through various instruments and displays. However, an increasing need to record and preserve this information and analyze it at a later time led to the development of data recorders and data acquisition systems.

Data acquisition systems have developed over time from electromechanical recorders (typically from one to four channels) to all electronic systems capable of measuring hundreds of variables simultaneously.

Early systems used paper charts and rolls of magnetic tape to permanently record the signals, but since the advent of computers, the amount of data and the speed with which they could be collected increased dramatically.

Computers with data acquisition systems will record extremely accurate, repeatable, reliable, and error-free data provided they are connected and operated according to the manufacturer’s recommended practices.

These practices include selecting the correct sensors for the application, the proper wire and shielded cable; and capturing the signals in proper magnitude, range, and frequency.

Data Acquisition Hardware

Hardware for data acquisition is what connects the sensors to the computer. The PCI-express ports on the motherboard or a USB port or also an Ethernet port or any other interface that a PC supports are used to link this gear to the computer. The data collection gear is responsible for receiving the signals from the sensors and converting them into digital signals that the computer can understand. This is the duty carried out by DAQ hardware.

Single – Ended Input Converters

The purpose of this component is to support the input of single-ended wires. Certain DAQ hardware models are stand-alone, meaning they may function independently of a computer connection. This is made feasible by a CPU and a computer unit that is built into the data acquisition system’s hardware. Real-time data representation is something that standalone data capture technology may assist users with. Solo oscilloscopes and other data loggers that measure certain data are excellent examples of DAQ equipment that operate independently of a computer.

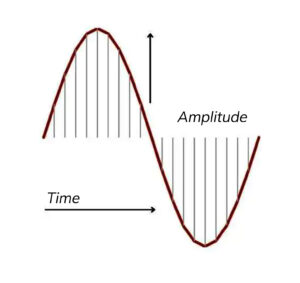

Data Sampling Rate

The sample rate also referred to as the sampling frequency or Fs, is established by common sense and the type of process under observation. Transducers provide signals for digital data capture, which involves a computer digitizing the signals. A computer, however, cannot hold continuous analog time waveforms; instead, it can only store samples of the signals. The number of samples obtained from a continuous signal per unit of time, which can be expressed in hertz, is essentially the sampling rate or frequency.

The sample rate is one component of data collection that might affect how a trend is interpreted. A sluggish sample rate can cause significant patterns to be obscured or overlooked. The old-fashioned justification of insufficient memory or disk space did not hold for computers of today.

To comprehend data acquisition, one must have a solid understanding of sample rates. When conducting testing, clients frequently desire quick sample rates, but the decision between short-term and long-term testing isn’t fixed. It depends on the type of signal being measured. If a signal has high-frequency components that need capturing, a higher sampling rate is essential, regardless of whether the testing duration is short or long-term. Depending on the client’s needs, data storage can take many forms.

Data Acquisition Types:

The types of DAQs are as follows:

- Analog DAQ

- Digital DAQ

Analog Data Acquisition Systems:

The ability to convert analog signals from the real world into digital data for processing and analysis makes analog data acquisition systems (DAS) useful in a variety of industries.

These systems are made up of signal conditioning circuitry that amplifies, filters, and preprocesses the signals in addition to sensors that record analog data such as voltage or current.

Analog-to-digital converters (ADCs) are used to transform these analog signals into a format that computers and microcontrollers can use for storage and analysis.

Scientific research, medical diagnostics, industrial automation, and environmental monitoring are just a few of the industries that use analog DAS.

By guaranteeing data correctness, precision, and dependability, it enables enterprises to regulate procedures, keep an eye on important factors, and make well-informed judgments.

These systems are adaptable instruments that help progress in numerous fields by bridging the gap between digital data processing and the actual environment.

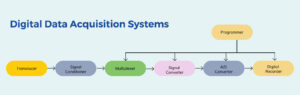

Digital Data Acquisition Systems:

To collect and analyze data from sensors, instruments, and sources in a format, digital data acquisition systems, or DAS, are essential. They are advantageous to all industries.

Accuracy is guaranteed by these systems by digitizing analog signals. Reduce the amount of data lost during storage and transmission.

Digital DAS typically consists of parts like ADCs, microcontrollers, and data storage units and offers real-time data for control and analysis. Process dependability and efficiency are greatly increased as a result.

Additionally, digital DAS integrates easily into computer-based management and monitoring systems and offers adaptability in handling different types of sensors.

As a result, they are now used as tools in a variety of domains, including environmental investigations, medical monitoring, industrial automation, and research.

Their ability to effectively collect, process, and disseminate information is important for improving procedures in various industries and for helping people make well-informed decisions.

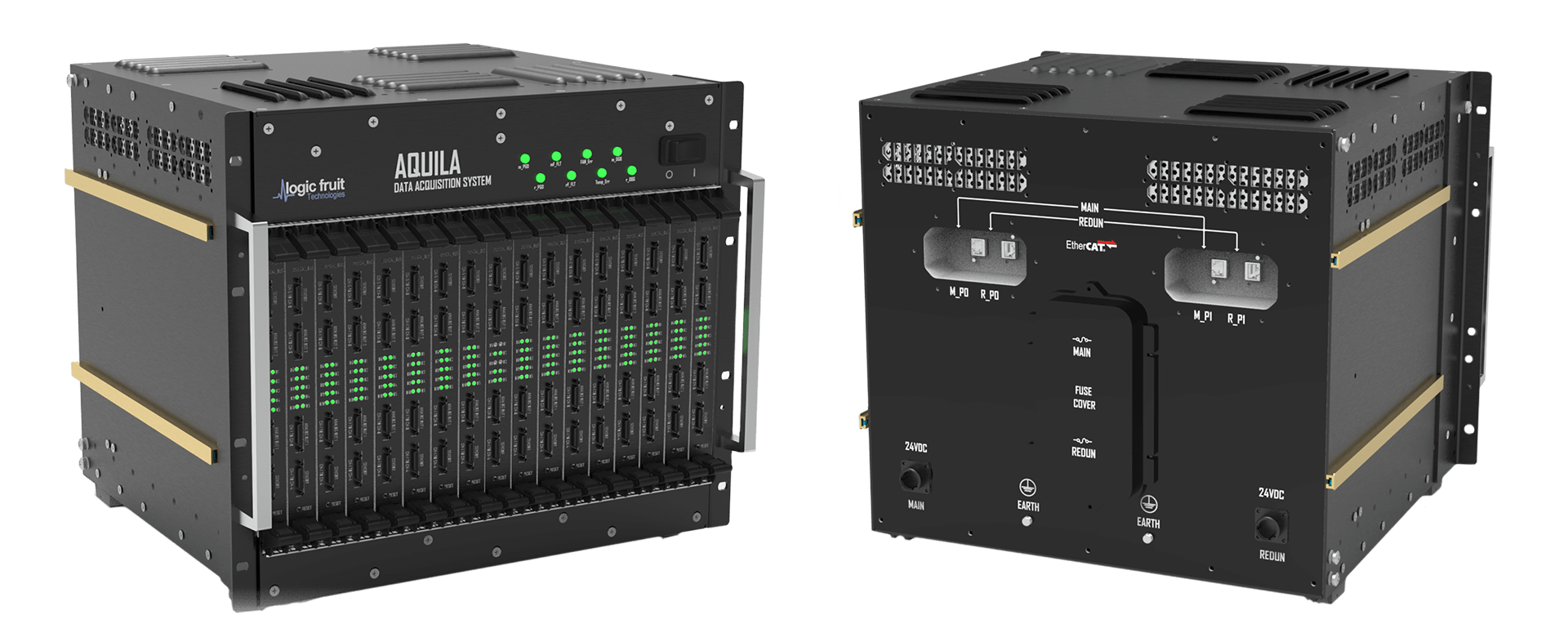

Rack Mountable Data Acquisition System

In the data acquisition systems that are being used to measure multiple parameters from hundreds of sensors in a laboratory or test bench, multiple data acquisition cards are mounted in chassis and these chassis are mounted on a 19” Rack enclosure.

In such a complex environment, rack mounting DAS provides proper distribution of cabling and physical protection to the system.

Logic Fruit Technologies AQUILA Data Acquisition System is an example of a Rack mounting Data acquisition system.

Stand-alone Data Acquisition System

Standalone Data Acquisition systems are smaller form factors, few channels, and easy pluggable data acquisition systems. These data acquisition systems are easy to set up. It can be plugged into our standard PC with an acquisition application running on it.

AQUILA Standalone DAS from Logic Fruit Technologies is an example of Standalone DAS.

Data Acquisition Options

There are a wide variety of systems to choose from:

Data Loggers

Data logging is the process of documenting data gathered over time. The data can be temperature, voltages, current, and humidity readings, depending on the application.

A data logger is a standalone data-gathering system that includes an embedded CPU and pre-defined software. Because they are portable, data loggers can function as standalone devices and are widely used.

Every data logger has local storage for data storage, and some include SD card slots for added memory. Data recorders with web configuration and network-sharing capabilities are available.

Some data loggers are battery-powered for even more portability.

Data Acquisition Devices

Signal conditioning and an analog to digital converter are features of data capture devices (USB, Ethernet, PCI, etc.), but they require a computer to work.

These devices are a popular option since they are versatile and valuable in many applications.

Users of plug-in devices can choose between a programming environment like PythonTM, C++®, DASYLab®, MATLAB®, and NI LabVIEWTM or pre-configured data acquisition software like DAQamiTM.

Data acquisition devices provide a flexible solution for your particular application with various BUS options and the freedom to use your favorite software.

Data Acquisition Systems

Systems with a high channel count and complexity that combine and synchronize many sensor types are built for modular data gathering.

Although more challenging to use and integrate, these systems are very adaptable.

The most expensive data acquisition option is a modular system, yet many applications need the characteristics that a PXI-compatible data acquisition system can only offer.

Measurement Process of DAQ

Real-world signals are translated into the digital realm during data capture to display, store, and analyze.

Actual phenomena must first be measured in the analog or the physical world we live in before being transferred to the digital domain.

Numerous sensors and signal conditioning circuitry are used in this procedure.

Analog-to-digital converters (ADCs) sample the outputs before writing them in a time-based stream to the previously described digital memory medium. These systems are commonly referred to as measurement systems.

Let’s examine each of these links in the chain individually.

- Sensors or Transducers

- Signal conditioners

- Isolation

- Filtering

- Analog-to-digital converters (ADCs)

- Data storage

- Data visualization

- Data analysis

Sensors or Transducers

A sensor is the first step in measuring a physical phenomenon by continuous motion, such as temperature, sound level, or vibration.

A transducer is another name for a sensor. A sensor transforms an observable physical phenomenon into an electrical signal.

Everyday activities include the usage of sensors. For instance, an ancient sort of sensor used to measure temperature is the standard mercury thermometer.

It uses colored mercury in a closed tube and depends on the fact that this chemical responds consistently and linearly to temperature variations.

We can only reasonably accurately determine the temperature by looking at the thermometer by marking the tube with temperature numbers.

Of course, there is only a visual output and no analog output. Although handy in the oven or outside the kitchen window, this simple thermometer is unsuitable for data collecting.

Thermocouples, thermistors, RTDs (Resistance Temperature Detectors), and even infrared temperature detectors are different types of sensors developed to measure temperatures.

Millions of these sensors are used daily for various purposes, including measuring temperature in pharmaceutical manufacturing and displaying engine temperature on dashboards.

Temperature measurement is used in almost every industry.

Of course, numerous additional types of sensors have been developed to gauge various other physical phenomena.

- Load cells: for measuring weight and load

- LVDT sensors: LVDTs are used to measure displacement in distance

- Accelerometers: measuring vibration and shock

- Microphones: for measuring sound,

- Strain gauges: to measure strain on an object, e.g., measure force, pressure, tension, weight, etc.,

- Current transducers: for measuring AC or DC,

- and countless more.

The electrical output of a sensor can be a voltage, current, resistance, or another electrical characteristic that changes over time, depending on the type of sensor.

The input of a signal conditioner, which we will discuss in the next section, is often connected to the output of these analog sensors.

Signal Conditioners

Signal conditioners’ job is to take the output from analog sensors and get it ready for digital sampling.

Suppose we stick with the thermocouple as an example.

The sensor’s output needs to be linearized by the signal conditioning circuitry, which also needs to provide isolation and amplification to raise the very low voltage to a usable level for digitizing.

From analog signal sources to digitalized data ready for processing by computer and software

The manufacturer builds each signal conditioning circuitry to carry out the fundamental normalization of the sensor output, guarantee its linearity and fidelity to the source phenomena, and get it ready for digitizing.

Additionally, because each type of sensor is unique, the signal conditioners must adapt to each type of sensor flawlessly.

Isolation Barriers (Galvanic Isolation)

Electrical isolation, also called galvanic isolation, separates a circuit from other sources of electrical potential.

This is crucial for measuring systems since most signals are present at relatively low levels and can be strongly impacted by external electrical potentials, leading to inaccurate measurements.

Both AC and DC potentials can act as interfering forces.

For instance, placing a sensor directly on a test object (such as a power supply) that has a potential above ground (i.e., not at 0V) might cause a signal to be DC-offset by hundreds of volts.

AC signals produced by other electrical components in the signal path or the vicinity of the test site might likewise be considered electrical interference or noise.

For instance, the room’s fluorescent lights can emit 400Hz, which sensitive sensors can detect.

Because of this, the best data collection systems include separated inputs to protect the signal chain’s integrity and guarantee that the sensor outputs match what has been read. Today, several different types of isolation techniques are used.

Filtering

Electrical interference or noise can impact almost any signal we seek to measure. This can be caused by several things, such as simple voltage potentials between the sensor or measurement device and the object being tested or ambient electromagnetic fields that can be produced into high-gain signal lines.

To eliminate these interferences and improve measurements, the best signal conditioning systems include adjustable filtering that the engineer can utilize.

Filters are usually expressed in terms of the band that they operate upon. There are four basic types of signal filters:

- Low-pass filter: this filter reduces or “rolls off” starting at a given frequency and those above it.

- High-pass filter: does the opposite and allows frequencies to pass above a given frequency.

- Band-pass and band-reject filters: pass or stop (reject) frequencies between two given values.

Analog-to-Digital Converters (ADCs or AD Converters)

Analog signals are typically produced as the output of physical measuring signal circumstances.

This signal must be transformed into a succession of fast digital values so that the data acquisition system can display and store it.

To transform this signal, an A/D card or A/D subsystem is employed.

AD converter scheme – converts the analog signal into digital domain data

ADCs can be multiplexed or single converters per channel, among other variations. A single analog-to-digital converter is used in a multiplexed ADC system to convert numerous signals from the analog to the digital domain.

This is accomplished by multiplexing the analog signals into the ADC one at a time.

This method is less expensive than using one ADC chip for each channel.

On the other hand, because only one signal can ever be translated at a time, it is impossible to accurately align the signals on the time axis. A timing skew between channels, therefore, always exists.

8-bit ADCs were widely used when data capture first started. As of this writing, most data acquisition systems intended for dynamic measurements use 24-bit ADCs as standard and 16-bit ADCs are frequently regarded as the absolute minimum resolution for signals in general.

The sample rate refers to the speed at which the signals are transformed.

Since the measurements fluctuate slowly in some applications, a high rate is unnecessary, like most temperature measurements.

However, many other measurands, such as AC voltages and currents, shock, and vibration, demand sample rates of at least tens of thousands of samples per second. The T or X-axis of measurement is regarded as being the sampling rate.

ADCs with different resolutions are available on the Y or vertical axis. These days, 16-bit and 24-bit are the most popular. It is theoretically possible to digitize an incoming signal with a resolution of one part in 65,535 (2^16 = 65,536) using an ADC with a 16-bit resolution.

Although this figure is lowered by noise and quantization error, among other things, it offers a useful baseline for comparison. Systems with 24-bit ADCs provide 2^24 = 16,777,216 because each bit of resolution is essentially twice the quantization resolution. As a result, the Y-axis may divide an incoming one-volt signal into more than 16 million steps.

For dynamic signal analysis, including vibration and shock, ADCs with high amplitude axis resolution and high sample rates work well. For thermocouples and other measurands with a large amplitude range and slow state changes, low sample rates and high amplitude axis resolution are ideal.

In every dynamic measurement application, ADCs with anti-aliasing filtering (AAF) are ideal as they guard against measuring errors resulting from sampling a signal at an unsuitable rate. When a fast-changing signal is sampled too infrequently, a spurious signal known as aliasing is produced.

The computer subsystem processes our signals, also known as measurands, in a few different ways after they have been transformed into digital. First and foremost, the test operator can visually evaluate and review them by viewing them on the screen of the device. A time-history display, often known as a “strip chart” (Y/T) or numerical display, is one of the most widely used data formats displayed by most DAQ systems. However, numerous systems on the market today offer additional display formats, such as bar graphs, X-Y graphs, and more.

Data Storage

Modern data acquisition systems generally transfer data from the ADC subsystem to long-term storage using a solid-state hard disc drive (SSD or HDD). The data can be examined after the test by writing it to a disc.

Most DAQ systems enable data export to several file formats for analysis using external software applications. Standard data formats include UNV (Universal File Format), CSV (Comma Separated Values), and others.

Data Visualization and Display

The capacity to visualize the data in real-time while it is being stored is one of the most critical features of any DAQ system.

Systems often use a flat-screen display, either integrated or independent, that may be set up in different visual forms.

Waveform data can almost always be shown in numerical form and as Y/T waveforms across a graph or grid.

Using bar graph meters, FFT (Fast Fourier Transform) frequency/magnitude graphs and other graphical standards is also possible.

- Recorders: horizontal, vertical, and XY recorder

- Oscilloscope: scope, scope 3D, vectorscope

- FFT: FFT, 3D FFT, Harmonic FFT, and Octave

- Meters: digital, analog, horizontal/vertical bar meters

- Graphs: 2D, 3D graph, Octave, Orbit, Campbell plot

- Video: standard video display and thermal video display with temperature indicators

- GPS: positioning display with interactive Open Street Map layering support

- Control: button, switch, knob, slider, user input

- Combustion analysis: P-V diagram and combustion scope

- Rotor balancer: for field balancing

- Automotive: 3D polygon for displaying moving objects

- Aerospace: altitude or artificial horizon indicator

- DSA/NVH: Modal circle

- Other: 2D/3D table, image, text, line, overload indicator, indicator lamp, note

Data Analysis

Data acquisition systems offer an essential visual reference for the real-time status of the test.

Data analysis tools that are either included in the DAQ system itself or that are part of outside data analysis software can be used to study the data after it has been stored in the DAQ system.

As was already said, the vast majority of DAQ systems currently available on the market have several built-in data export filters that transform the system’s proprietary data format into other data formats for offline analysis.

Various Display and Analysis windows of AQUILA DAS ACQ Software

Data Acquisition Signal Used

Voltage Signals

The signal that DAQ systems use the most frequently is the voltage signal. A voltage signal is produced, for instance, by thermocouples, gas concentration probes, and strain gauge bridge circuits.

An analog-to-digital converter is used by data acquisition hardware to first condition the signal before converting it to a digital number. The computer stores this digital value.

A few millivolts to a few volts, for example, are examples of low-voltage inputs that data-gathering systems can frequently handle directly.

Current Signals

Due to its greater resistance to background noise, current is typically utilized for signal transmission in loud conditions. A data collection system records the value of the current flow and stores it in a computer for further analysis.

Power Signals

When the current signal is sensed using a current-sensing resistor, signals from the electrical power supply can be observed, and high-voltage signals can be broken down using resistive dividers. To measure and store data to monitor the power signals, the data acquisition system will receive data from the current-sensing resistor.

Instead, the temperature differential between the thermocouple’s two wires which are composed of two distinct metals collected at the junction of the wires, and the cold junction the location where the thermocouple wires terminate determines the voltage.

Thermocouples

The low voltage signal that these sensors produce is usually in the range of a few millivolts. The voltage and temperature have a non-linear relationship.

Depending on the type of thermocouple being used, the accuracy will change.

Resistance

To measure resistance, a current source and a standard voltage input are used. The voltage drop over an unknown resistance is measured when current passes through it. The data collecting system then records this voltage drop.

Strain Gauge Bridges

These bridges offer a unique instance of measuring resistance. The basis for the operation of strain gauge bridges is the concept of electrical conductance and how it varies with conductor geometry.

The resistance of the gauge, which changes when an applied strain distorts it, is measured using a Wheatstone bridge arrangement. They gauge the minute variations between the two circuits of a Wheatstone bridge.

As a result, rather than focusing on exact measurements, strain measurement frequently involves measuring variations from the starting values.

Thus, it is necessary to know the initial values. These might be big enough to offset the ensuing alterations in the bridge imbalance brought on by applied strain.

To provide the necessary dynamic signal range, a high-resolution analog-to-digital converter is used.

Digital Signals

Logic signals are those generated by switches and other digital output devices. On(1) or off(0) is the sensed value for these signals.

To find the switch status on volt-free contacts—where there is no external voltage switching—a tiny sensing voltage is supplied. To be compatible with TTL levels, this is typically 5V.

The voltage level itself can be used to determine the logic state when voltage is being altered. The voltage levels, such as TTL up to 12 V logic or 24 V DC, dictate the type of input used.

Counter-timer-type inputs need to be taken into account when the digital signals are changing quickly and starting to resemble pulse trains.

Factors affecting the measurement accuracy

The quality of the measuring tool is only one of many variables that affect measurement accuracy. As a result, it is usually recommended that the user take readings in a highly neutral environment.

The following list includes several typical disturbances that have an impact on measurement accuracy:

- Temperature: Most of the sensors we employ, particularly piezoelectric, are somewhat temperature-dependent. Techniques for temperature correction are utilized to offset this effect.

- Calibration Errors: Calibration is required once a DAQ system has been configured to provide the most precise readings. Without calibrating the measurement apparatus, you’ll start getting inaccurate readings.

- Human Errors: One of the most frequent errors seen while taking measurements is human error, ranging from forgetting to perform an essential step during the measurement to a poor test setup. For this reason, most experiments and tests come with a protocol. Any experimental observation must be carried out following it to be effective.

- Humidity: It’s generally not a good idea to take measurements when it’s excessively humid since electrical components can fail when the humidity is too high.

- Effect of Friction, Hysteresis, or Other Electrical Noise: Electricity’s magnetic properties can significantly impact the nearby object, especially if it’s made of metal. Measurement errors may result from taking measurements while overlapping electrical noise is present.

- Vibrations: Sensor readings can be affected by vibrations unless you are explicitly measuring them! The test bench must be steady and free from unwelcome vibrations or friction.

- Light: Light may seem like an odd error, but if you are measuring the intensity of light coming from a source and there is another light leakage, it might result in major measuring instabilities.

- Nonlinearity: Nonlinearity error happens when the sensor output curve doesn’t vary proportionally to the input curve. This shows that the measuring device cannot scale appropriately with a different load or input.

Benefits of using DAQ devices

Let’s discuss the benefits of using a Data Acquisition device for measurements.

- DAQ Systems are Industry-Leading Measurement Devices

The fact that you are employing a measurement method that is widely used is the main advantage. A DAQ gadget is an excellent option for engineers, researchers, and scientists who want to collect accurate data on their tests because of its capacity to link various sensors and function in conjunction with modern computers.

- DAQ Systems are Highly Versatile

DAQ systems are offered as integrated measurement systems with various measurement modes that can measure various attributes. Additionally, they are created as specialized tools that can only measure a particular property.

- Documentation – Eliminates Data Redundancy

Documentation capacity is one of a DAQ system’s distinguishing characteristics. With the computer automatically recording the data, you may run various tests one after the other without having to write down the results or worry about forgetting the readings.

- Flexibility

Building mixed-measurement systems with specialized functions is made feasible by data acquisition systems.

- Scalable

A wide range of hardware solutions are available, from processing small amounts of data to managing several data-gathering devices that are coordinated to work as a single, synchronized application.

- High Efficiency and Reliability of Processes

Vital parameters are monitored in numerous significant establishments worldwide through the use of data-gathering systems. The data that data collection systems gather is utilized to guarantee dependability, increase efficiency, and ensure that the equipment is running safely.

- Faster Analysis and Resolution of Problems

This is advantageous to technicians since it enables them to address issues more quickly and ensure maximum operation by making any necessary repairs.

- Reduced Data Redundancy

Leading data acquisition solutions enable businesses to reduce redundant data and embrace technology, all while simplifying the process of analyzing the gathered data. The staff may work without interruptions which could enhance their productivity thanks to these technologies.

- Decrease in Update Errors

Manual data input procedures can now be automated with the help of data-gathering technologies. By removing human error, automation lowers errors and frees up staff members’ time for other tasks.

- Improved Data Security

The human element has been removed because data collection is now automated and objective. As a result, there are fewer security risks connected to data management, analysis, and storage.

- Cost-Effectiveness

Work processes become more cost-effective since data is entered more quickly, less memory is needed, and DAQ systems enable the immediate recovery of this information.

- Quality Control

Data gathering systems can verify that a system is adhering to design guidelines so that a product fulfills user requirements. These systems also can test products to see whether they meet quality standards before they are manufactured. They additionally offer a way to examine faulty products.

- Better File Processing and Transfer Capabilities

A computer is used to store the data acquired by a data acquisition system, after which it can be processed or examined as the user sees fit. A computer also facilitates any further data transfers to other devices that might be necessary.

Data collection systems make it possible to gather important, unbiased information that may be used to boost economic prosperity and an organization’s performance.

Data acquisition systems provide an organization with more control over its operations and enable a quicker reaction to any potential failures. Data acquisition systems aim to enhance and optimize an organization’s productivity while simultaneously optimizing the caliber of their goods and services.

Important applications of the DAQ system

Many different industries make use of DAQ systems. Let’s talk about a few of these computer-based measurement systems to grasp the adaptability of these computer-based measurement systems.

- Electronics: Electronics is among the leading examples of a sector where DAQ implementation is standard. The DAQ systems are used to evaluate various factors, including heat production, conductivity, resistance, magnetics, and more, involved in the design of electronics.

- Automotive Industry: DAQ machines are frequently seen in automotive manufacturing facilities to check the quality of the produced parts.

- Imaging: DAQ devices are frequently used for quality testing image equipment, including cameras, lenses, and scientific equipment like scanners and microscopes.

- Laser Technology: Testing laser performance, light intensity, and color can be done with DAQ devices.

- Sonar – Radar: testing the effectiveness and efficiency of remote sensing systems like radar and sonar.

- Industrial Machines: Because industrial devices are designed to carry out a procedure repeatedly, repeatability is crucial. DAQ is frequently used to test the machines’ resistance to repetitive stresses.

- Non-destructive Testing (NDT): The analysis of acoustic emission phenomena, seismology, geology, ultrasonic measurements, and non-destructive testing of structures all use DAQ equipment.

- Advancing Scientific Exploration: Researchers in a variety of disciplines, including biology, physics, and environmental research, aerospace, space research depend on data gathering to gather information for their observations, simulations, and experiments, which helps them make discoveries and gain fresh perspectives.

- Enhancing Industrial Efficiency: In industrial environments, data capture systems are essential because they monitor production procedures, ensure product quality, and maximize overall productivity.

- Fostering Environmental Insights: By tracking important variables like air quality, water levels, and soil characteristics, environmental monitoring gains from data collection and helps with efficient environmental management and prompt disaster prediction.

- Revolutionizing Healthcare and Biomedical Studies: The field of healthcare uses physiological data collection and vital sign monitoring via medical device data collecting to improve diagnostic precision and advance scientific research.

- Elevating Automotive Evaluation: Data acquisition is a vital technique used in the automotive industry to test vehicle efficiency, safety features, and performance in a variety of settings, resulting in the development of safer and more effective vehicles.

- Industrial and Manufacturing Sectors: Data capture devices are used in manufacturing industries, like steel mills and other production units, as well as research labs, to monitor parameters. The information gathered can be utilized to guarantee the machinery runs securely, increase productivity, and assure dependability.

- Role in Environmental and Climate Monitoring: By providing accurate and up-to-date information to support scientists and decision-makers in comprehending and addressing environmental challenges, the data acquisition system (DAS) is essential to environmental monitoring.

Challenges, Limitations, and Solutions

- Accuracy and Calibration: Reliable data collecting depends on precise and well-calibrated sensors and devices.

- Data Integrity: It might be difficult to maintain data integrity during the acquisition process while also preventing noise and signal interference.

- Sampling Rates: Selecting the right sample rates is essential; a rate that is too high could result in data overload, while a rate that is too low could miss important data.

- Compatibility and Integration: Compatibility problems might make integrating several sensors and instruments from different vendors difficult.

- Different sources for different needs: The market is full of different data sellers. Every supplier has a specific market share. Selecting the finest data provider has become more difficult due to the abundance of providers. Each supplier possesses unique strengths and disadvantages.

- Scale and complexity: Large-scale data arises, which makes handling it difficult. Big data is a problem that many financial and commercial organizations face. For handling vast amounts of data, conventional software and techniques are insufficient. Managing the growing intricacy of data presents significant challenges in and of itself.

- Different levels of Quality: Variations in data providers result in variations in data quality. Purchasing data from different marketplaces, like trade markets, yields low-cost, uneven-quality data over time. Clients must therefore make an effort to receive the data in a usable format.

- Security and Privacy challenges: There is a lot of data in reference data. Large data sets cannot be managed with standard software tools. To store and distribute reference data, appropriate sanity checks and security measures should be included.

Choosing the Right DAS Vendor

It is practically impossible to locate the ideal system and vendor because there are so many various parameters to measure and test scenarios to try.

You must ask a lot of questions to solve this issue and choose the best data-acquisition vendor for your needs. These four will help you get going:

- What’s the test environment? Automobile testing is conducted in a variety of settings, some of which are rather harsh. Seek for a data-acquisition system that can withstand a lot of shock and vibration, for example, if you need to collect data while doing tests on a Belgian Block course. What matters in this application is the system packaging; seek providers who say their systems are “shock-proof” or “ruggedized.”

- What parameters do you need to measure? Are you primarily interested in one parameter, such as pressure or torque, or does your application require you to measure a wide range of parameters? In theory, any data-acquisition system may be used to measure any parameter by using the appropriate sensors. Regretfully, it’s not quite that easy.

You must have some knowledge about the property being measured as well as the measurement technique to make reliable measurements. For instance, you must understand how pressure sensors operate to select the right one if you need to detect the coolant fluid’s pressure. If you lack such information, you might wish to select a system from a business that specializes in the kind of measurement you are doing.

- When must the testing start? Does developing software take time, or do you need to start gathering data right away? A fantastic system that will undoubtedly satisfy your wants can be developed with the help of certain organizations’ extensive selection of adaptable data-acquisition gear and software.

- How much support will a vendor provide? Choose a supplier who will assist you throughout the system’s lifetime, not just when you’re getting it up and running. Because modern data-acquisition systems are so complicated, troubleshooting them will still require assistance, even from a qualified instrumentation expert.

Purpose of Data Acquisition

A data acquisition system’s primary function is to gather and store data. However, they are also designed to offer data visualization and analysis in real-time and after recording.

Additionally, most data-collecting systems include built-in analytical and report production capabilities.

Combining data acquisition and control, where a superior DAQ system is closely coupled and timed with a real-time control system, is a recent breakthrough.

Engineers in various applications have varied needs, of course, but these essential talents are present in different degrees:

- Data recording

- Data storing

- Real-time data visualization

- Post-recording data review

- Data analysis using various mathematical and statistical calculations

- Report generation

LFT’s AQUILA data acquisition system offers a complete data recording, storing, visualization, analysis, and reporting solution in one complete package.

Data acquisition instrumentation is also heavily used in monitoring applications. Such examples are:

- Monitor the condition of complex machinery such as generators, motors, fans, etc.

- Monitor structural properties of buildings such as bridges, stadiums, etc.

- Monitor energy consumption and energy efficiency in the production process.

- And many other monitoring scenarios.

Conclusion

The process of gathering, storing, processing, and evaluating data is known as data acquisition systems. A variety of methods, including voltage, current, and power signals, are used to collect the data. Various kinds of data acquisition systems are employed. While some of them are all-in-one, multifunctional gadgets, others are specialized instruments meant to measure data based on a particular parameter. Many industries, such as the automotive, electronics, and laser technology sectors, can benefit from the application of data acquisition systems.

These systems have numerous advantages. They are dependable, quick, adaptable, and reasonably priced. Data recording for additional analysis can be done very effectively and conveniently with the use of data-gathering equipment. Because data collection is increasingly automated, data acquisition systems not only increase data security but also facilitate better user access to data while lowering mistake rates.

Data collection is essential to an organization’s ability to stay competitive, make wise decisions, and obtain insightful knowledge in today’s data-driven environment. The process of data acquisition entails gathering, analyzing, and organizing data from multiple sources, as this blog has discussed. Effective data collecting is critical for any type of business, small or large, aiming to improve customer understanding or operational efficiency.

In Conclusion, gathering data is the first step in any data-driven project that succeeds. It gives businesses the ability to make wise judgments, enhance internal procedures, and provide better customer service. You may use data acquisition to propel the success of your company by adhering to best practices, preserving data quality, and remaining flexible in the face of changing technology and data requirements.

FAQs

1) What are the 3 major components of a data acquisition system?

All data acquisition systems consist of three essential elements – Sensor, Signal Conditioning, and Analog-to-Digital Converter (ADC).

2) What are the requirements of a data acquisition system?

The components of data acquisition systems include:

- Sensors, to convert physical parameters to electrical signals.

- Signal conditioning circuitry, to convert sensor signals into a form that can be converted to digital values.

- Analog-to-digital converters, to convert conditioned sensor signals to digital values.

3) What are the applications of data acquisition systems?

The process of gathering, processing, storing, and using raw data from the real world is known as data acquisition. In the industry, data acquisition systems, or DAS, are commonly utilized.

They are used in management, testing, production, quality control, process control, and research and development, among other areas.

4) What is the main objective of the data acquisition system?

The data acquisition system (DAS), which gathers data from various PV system sensors, is a crucial component of any monitoring system.

After that, the DAS digitalizes the data for storage and transmits it to the control center for processing and display.

5) What is a real-life example of a data acquisition system in the industry?

A data gathering system, for instance, can be used to check the temperature of a heating coil that’s been used to heat an object to a particular temperature.

By monitoring its temperature, the heating coil’s effectiveness can be determined.

6) What is an analog data acquisition system?

Analog sensor data is gathered by a data acquisition system (DAS or DAQ), which then converts it into digital format for analysis and storage. A DAS can be included inside a computer or used independently. It might gather data from several channels.

7) What is the difference between analog and digital data acquisition systems?

Digital systems use discrete values to represent data, whereas analog systems use a continuous signal. Although digital systems are more complicated and need more bandwidth than analog systems, they are also typically more accurate and noise-immune.

8) Why is data acquisition important in machine learning?

Main Purpose of a Data Acquisition System (DAQ)

- Measure and Record Data: Collect data from diverse sensors and transducers.

- Analog-to-Digital Conversion: Convert analog signals from sensors into digital data.

- Processing and Analysis: Facilitate data processing and analysis using computers or data processing units.

9) What are the elements of a data acquisition system?

Combining sensors, measurement tools, and a computer is known as a data acquisition system. When gathering the information needed to comprehend electrical or physical processes, obtained data is processed using a data acquisition system.

10) How does a DAQ system work?

A system that receives analog inputs and converts them to digital signals is known as a digital signal processing unit (DAQ).

Following are the fundamental elements of a digital DAQ: Transducer that accepts analog signals and transforms them into an appropriate medium (electric signals, for example) for the device.