Introduction

In functional safety areas like rail, automotive, aerospace, and medical, where embedded systems are used more and more, it is becoming more and more important to ensure the software in those systems is safe. The creation of software must come first to ensure that.

However, the widespread use of these complex technologies also poses a serious threat to the dependability and safety of the system.

The functioning of the gadget and, in certain situations, even human lives could be at risk due to a software defect or vulnerability that could have far-reaching effects.

As a result, developers, engineers, and manufacturers now consider it essential and non-negotiable to ensure the safety and dependability of embedded software.

This blog discusses a variety of topics, including the significance of testing in safety compliance, embedded systems safety standard certifications, and the importance of safety compliance.

Definition of Embedded Systems

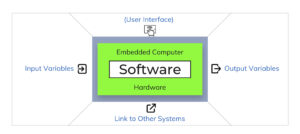

A microprocessor-based computer hardware system with software built to carry out a particular task, either standalone or as a component of a larger system, is called an embedded system.

An integrated circuit built to handle computing for real-time processes is at the center of it.

Embedded systems, as compared with desktop computers, servers, and other computing domains that are composed of discrete parts, are integrated into goods and comprise both hardware and software.

Importance of Safety Compliances in Embedded Systems

- Embedded product quality means the difference between life and death in crucial embedded system applications such as automobile control systems and medical equipment. Any integrated product feature malfunction or failure can result in dangerous or catastrophic circumstances that put human lives in jeopardy.

- Safety and mission-critical applications depend on data integrity to carry out their intended tasks, hence an embedded system’s security features must be enough to stop data leaks.

- Hazards and malfunctions in embedded systems are less likely when safety regulations and certifications are followed. For managing any risks and hazards during the product development process, these standards offer a thorough framework.

- Ensuring that features of embedded systems operate as intended in all situations requires strict embedded testing, validation, and verification procedures.

Industry Standards for Embedded Software Development

Several industry standards are followed throughout embedded software development to guarantee the systems’ interoperability, safety, and dependability.

Leading industry standards for embedded software development include the following:

ISO 26262 – Road Vehicles – Functional Safety

The international standard ISO 26262 addresses functional safety in car electrical and electronic systems. It focuses on safety-critical component lifecycles in their entirety, from conception to decommissioning.

The standard addresses system-level design, software, hardware, and other facets of automobile safety. By ensuring that any hazards are recognized, evaluated, and controlled throughout the development process, compliance with ISO 26262 helps lower the chance of mishaps and failures.

IEC 61508 – Functional Safety of Electrical/Electronic/Programmable Electronic Safety-Related Systems

A general standard for functional safety in a variety of industries, such as equipment, process control, and railway signaling systems, is IEC 61508.

It addresses safety-related electrical, electronic, and programmable electronic systems and offers a framework for handling safety during the system’s lifetime.

By ensuring that safety functions are carried out accurately and consistently, compliance with IEC 61508 helps to reduce the likelihood of mishaps and incidents.

DO-178C – Software Considerations in Airborne Systems and Equipment Certification

An industry standard for software development used in aircraft systems and equipment is DO-178C. It offers recommendations for guaranteeing the dependability and safety of software components and aids in proving adherence to airworthiness standards.

The standard addresses planning, designing, coding, testing, and verification, among other facets of software development.

Adherence to DO-178C guarantees that software utilized in aviation systems satisfies rigorous safety and performance standards.

IEC 62304 – Medical Device Software – Software Life Cycle Processes

An international standard for the creation of software for medical device development is IEC 62304. It offers a structure for overseeing software development procedures, guaranteeing that software for medical devices satisfies performance and safety standards.

The whole software lifecycle—from planning and design to maintenance and decommissioning—is covered by the standard.

Adherence to IEC 62304 aids in guaranteeing that software for medical devices is created, examined, and preserved in a way that reduces hazards to users and patients.

EN 50128 – Railway Applications – Communication, Signaling, and Processing Systems

A European standard called EN 50128 is utilized in the creation of software for railway applications, such as processing, signaling, and communication systems.

It offers recommendations for guaranteeing the dependability and safety of software components utilized in railway systems and aids in proving adherence to safety regulations.

The standard addresses planning, designing, coding, testing, and verification, among other facets of software development.

Adherence to EN 50128 guarantees that railway software satisfies rigorous safety and performance standards.

ISO/IEC 12207

The software lifecycle procedures for software development and maintenance are outlined in this standard. It offers a structure for overseeing software projects and guaranteeing quality all through the development phase.

ISO 9001

ISO 9001 is a widely accepted quality management standard that applies to many businesses, including those employing embedded systems, even though it is not specifically related to embedded software. Customer satisfaction and ongoing improvement are its main priorities.

IEEE 1012

For software verification and validation tasks like testing, reviews, and inspections, this standard offers guidelines. It aids in guaranteeing that the program satisfies its prerequisites.

ISO/IEC 20246

The safety of artificial intelligence systems, especially those found in embedded devices, is covered by this new standard. It seeks to define guidelines and procedures for reducing the hazards connected to AI applications.

To achieve safety, security, and dependability in embedded software development, developers and organizations must comprehend and adhere to these requirements.

Adherence to these guidelines not only guarantees software quality but also facilitates regulatory clearances and fosters consumer and stakeholder trust.

Other Relevant Safety Standards and Their Applications

For various applications and industries, there are a plethora of additional safety regulations. In many industries, including aerospace, automotive, medical, railroad, and industrial automation, these standards contribute to ensuring the security and dependability of embedded systems.

To achieve industry-specific safety regulations and secure market acceptance for the finished product, adherence to these criteria is crucial.

Because each embedded system application is unique, developers and engineers must determine which safety requirements apply to them and follow them.

How to Create a Secure and Reliable Embedded System?

Throughout the development lifecycle, a methodical and disciplined approach is necessary to create an embedded system that is both secure and dependable. To reach this objective, consider the following crucial actions and best practices:

Requirements Analysis: Begin by outlining all of the system’s needs, including functional and non-functional, such as dependability, safety, and security. Determine potential dangers to safety at the outset of the process.

Secure Design: Make use of secure design techniques and ideas. Use strategies like isolation, defense in depth, and least privilege to reduce the attack surface and any potential weak points.

Threat Modeling: To find potential attack pathways and security threats, do a thorough threat modeling exercise. Take suitable design decisions and actions to address these threats.

Code Reviews: To find security holes and coding errors, do routine code reviews. To identify any problems early on, employ static code analysis tools and adhere to secure coding practices.

Testing and Validation: Functional, integration, unit, and security testing are all included in this. Undertake penetration tests and vulnerability assessments to evaluate the system’s ability to withstand attacks.

Use Trusted Libraries and Components: Make use of reputable and well-established libraries, frameworks, and parts. When integrating third-party software, exercise caution and make sure it is updated and patched regularly.

Secure Communication: Use encryption and secure communication protocols (such as TLS/SSL) if the embedded system communicates via a network to safeguard data while it is in transit.

Firmware Updates and Patch Management: Make plans for timely and safe firmware updates. Establish a secure updating system that checks the updates’ integrity and authenticity.

Access Control: To guarantee that only authorized users can access sensitive functions and data, implement strong access control measures.

Secure Boot: Establish a safe boot procedure to guarantee that the system boots up with only verified and trusted code.

Secure Supply Chain Management: Ensure that all components and software in the supply chain are from trusted sources and have not been tampered with.

Compliance with Standards: Follow relevant industry standards and guidelines (e.g., ISO 26262, IEC 61508, etc.) to ensure safety and reliability compliance.

Continuous Monitoring and Updates: Establish systems for ongoing security and system performance monitoring. Update the system frequently to fix vulnerabilities that are found.

Documentation and Training: Ensure that the architecture, design, and security elements of the system are all thoroughly documented. Educate users and developers about security best practices and associated hazards.

These procedures can be greatly improved to increase the security and dependability of the embedded system development process. This will lessen the possibility of potential vulnerabilities and guarantee a reliable and strong end product.

The Role of Safety Standards and Certifications in Product Development

Ensuring Product Safety and Reliability

Ensuring the safety and dependability of products is greatly dependent on safety regulations and certifications. Developers and manufacturers can systematically discover, evaluate, and reduce any dangers and risks connected with their goods by complying with specified safety standards.

Certifications provide an extra degree of assurance by confirming that a product satisfies safety regulations and operates as intended.

Reducing the Risk of Accidents and Failures

Accidents and embedded system failures are less likely when safety requirements and certifications are followed. During the product development process, these standards offer a thorough framework for managing potential risks and hazards.

Developers can reduce the possibility of mishaps and system malfunctions by adhering to the recommendations and best practices specified in safety standards, therefore improving the dependability and safety of their products.

Facilitating International Trade and Market Acceptance

To promote global trade and market acceptance, safety standards and certifications are vital. Manufacturers may show their dedication to quality and safety by adhering to internationally recognized safety standards, which will win over customers, regulators, and other stakeholders to their products.

Specifically, certifications reduce the complexity of getting regulatory permission and opening up new markets by acting as a widely recognized verification of a product’s performance and safety.

Avoiding Legal Issues and Liability Claims

Manufacturers can help themselves avoid legal problems and responsibility claims related to product failures and accidents by adhering to safety standards and certifications.

Manufacturers can demonstrate their adherence to safety standards and that they have taken the required precautions to guarantee the dependability and safety of their products.

In the event of a product-related accident, this can be quite helpful as it may lessen responsibility claims and shield the manufacturer from possible legal consequences.

Integrating Safety Standards into the Development Process

Understanding the Safety Requirements of Your Specific Industry

While developing embedded systems, specific safety regulations for each industry must be taken into consideration. Engineers and developers must comprehend the particular safety standards and laws that apply to their sector.

With the use of this knowledge, they may create products that satisfy the essential performance and safety standards, thereby guaranteeing the dependability and safety of their systems.

Incorporating Safety Standards Early in the Development Process

Embedding safety criteria from the beginning of the development process is crucial to producing dependable and safe embedded systems. Developers can proactively identify and mitigate potential hazards and risks by taking safety criteria into account during the first phases of design.

This approach ultimately reduces the probability of accidents and system failures. Because it reduces the need for expensive redesigns and retesting later in the development cycle, early incorporation of safety standards also enables more effective development procedures.

Following Best Practices and Guidelines for Safety-Critical Systems Development

Ensuring the safety and dependability of embedded systems requires strict adherence to best practices and guidelines for safety-critical systems development. Strict design processes, exhaustive testing and verification procedures, and exhaustive documenting of development operations are some examples of these best practices.

Developers can decrease the risk of accidents and malfunctions while meeting industry safety regulations by adhering to these rules and creating embedded systems.

Implementing Processes for Ongoing Safety Compliance and Maintenance

For embedded systems to remain safe and reliable, continuous safety compliance and maintenance are necessary. This entails putting procedures in place for tracking system performance, carrying out routine safety evaluations, and resolving any found vulnerabilities or safety issues.

Developers may assist in guaranteeing that their embedded systems continue to meet the essential safety criteria and reliably carry out their intended functions throughout their lifecycle by adopting a proactive approach to safety compliance and maintenance.

Verification and Validation

Verification in embedded product development

In essence, verification is the process of determining whether the development satisfies the specifications set forth for the particular phase.

It covers a variety of tasks such as reviewing the code during the product development process, conducting design reviews, and looking at the system and business requirements.

Static testing is a term used to describe this kind of testing, which means ensuring that the product is being developed by the established rules and guidelines and that we are producing the right product.

Validation of embedded products

In contrast, validation refers to the assessment of a system or component at any point during the development process to ascertain whether it satisfies the specified requirements.

It entails determining whether the product performs as intended in the context and application of real-world use.

Working with the actual physical product and verifying its functionality using one or more well-defined testing procedures are the main tasks involved in embedded product development scenarios.

Verification Methodologies

Numerous standards, including ISO 26262 Functional Safety for automotive applications and ASME V&V 40 for medical equipment, specify the verification and validation processes that must be adhered to according to the use cases.

They are all characterized by meticulous examination and review at every level, with differing degrees of specifics and documentation.

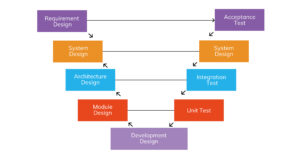

The typical V model for validation and verification is shown in the diagram below.

To assess the embedded product’s verification, the following documentations are generally required.

- Business Requirements Documents

- Software/System Requirements Document

- High-Level Design Document

- Low-level design document

Validation Methodologies

The validation process is arguably the most apparent because it involves an external stakeholder and provides evidence that the generated product complies with his expectations. The underlying business needs and complexity dictate the necessity for the several tests that are involved, which are listed below.

- Unit Testing

- Integration Testing

- System/Functional Testing

- Acceptance Testing

- Regression testing

- Performance testing

- Security Testing

Let us take a look at each of the testing methods.

Unit Testing

Unit Test Plans, or UTPs, are developed in the module development stage of the V-Model. These strategies are carried out to identify and address mistakes made during the development phase. The smallest autonomous entity is represented by a unit or module, such as a program module.

The accuracy with which this little entity operates when separated from other codes or units is verified by unit testing. Tools that can be used in unit testing are Google, JUnit, etc.

Integration Testing

After unit testing is finished in the development life cycle, integration testing is the next stage of the software testing process. In the architectural design phase, integration test plans are created.

The purpose of these tests is to confirm that groups that have been individually formed and tested can effectively interact and communicate with one another.

This stage of testing is crucial for ensuring that different units or components work together seamlessly, evaluating their functions, and determining how well they can function as a single unit.

The Vector tool, the LDRA Suite, and other tools are utilized in integration testing.

System/Functional Testing

After integration testing, system testing is the third stage of the testing procedure. As the name implies, this entails testing the system as a whole to see if the finished result satisfies the required functional requirements. System testing is very important because it takes place right before the product is almost ready to ship.

This stage enables testing in a setting that nearly replicates what users will encounter after the product is made available.

TestBot, Embunit, and other tools are suggested for usage in functional testing.

Acceptance testing

Acceptance testing and business needs analysis go hand in hand. From the pool of system test cases, important positive test cases are chosen at this step to be used in acceptance testing. This entails testing the product in real-world user settings.

The purpose of the test is to find out if the consumers or their representatives are willing to adopt the designed system. Robot Framework, TestRail, and other programs are some of the tools used in acceptance testing.

Regression testing:

Regression testing is the process of re-running a portion of the system, integration, and unit tests following a code change. The main objective is to confirm that the security, functionality, or performance of the product has not been adversely impacted by the recent code modification.

To ensure that the most recent changes do not have any negative impacts, this procedure involves identifying the changes made to the code and the related workflows.

It also includes updating the product while making sure that the embedded product retains prior configurations and data points. Regression testing uses a variety of tools, such as TestBot and Robot Framework.

Performance testing

Evaluating an embedded system or product’s speed, responsiveness, and efficiency under varied workloads and situations is known as embedded product performance testing. This kind of testing evaluates the product’s performance in terms of memory usage, processing speed, and resource utilization.

Its goal is to guarantee that the embedded system can perform as required and can carry out its intended functions without suffering from notable hiccups or malfunctions. To find possible performance bottlenecks and optimize the system for best performance in real-world situations, testing is essential.

Case Studies: Successful Implementation of Safety Standards and Certifications in Embedded Systems

Products that have successfully obtained safety certification as examples. Numerous goods from a variety of industries have been successfully certified as safe, proving their dedication to dependability and safety. Some instances are:

- Road vehicles are guaranteed to have functional safety thanks to the certification of automotive electronic control units (ECUs) to ISO 26262.

- Aircraft systems and equipment that have earned DO-178C certification, proving they adhere to strict aviation safety regulations.

- Software components in life-critical applications are guaranteed to be safe and reliable by medical devices that have embedded software certified to IEC 62304.

- Systems for railway processing, signaling, and communication that have earned EN 50128 certification, proving compliance with industry safety standards.

Conclusion

For every embedded software project to be successful, safety, dependability, and data integrity are essential components.

Having an experienced IT partner becomes strategically necessary for businesses and organizations to attain these fundamental qualities.

The complexity of embedded systems necessitates a careful approach, best carried out by experienced experts familiar with the subtleties of integrating hardware and software.

Finally, we urge manufacturers and developers to give safety compliance priority in any upcoming embedded systems projects.

Businesses may produce products that not only meet the strict safety requirements of their respective industries but also enhance the general safety and well-being of end users by comprehending and abiding by the pertinent safety standards, implementing safety-focused development processes, and obtaining the necessary certifications.

![Advanced Driver Assistance System [ADAS] Everything You Needs to Know](https://www.logic-fruit.com/wp-content/uploads/2022/10/Advanced-driver-assistance-systems-Thumbnail.jpg)