The aerospace industry has undergone a drastic transformation over the years, with automation being one of the major factors behind it.

Gone are those days when all processes were extremely manual; today, advanced technology systems accomplish the best manufacturing, assembly, and maintenance operations.

The introduction of robotics, AI, and digital tools has ensured the utmost precision, reduction in operational cost, and lower incidences of human error.

Besides efficiency, automation is also a key factor in safety and reliability assurance in aerospace operations. From precision aircraft component design to predictive maintenance and real-time system monitoring, automated technologies are making air travel secure and reliable.

With aerospace ever evolving, automation has become a building block toward learning new performance and innovation standards for the industry.

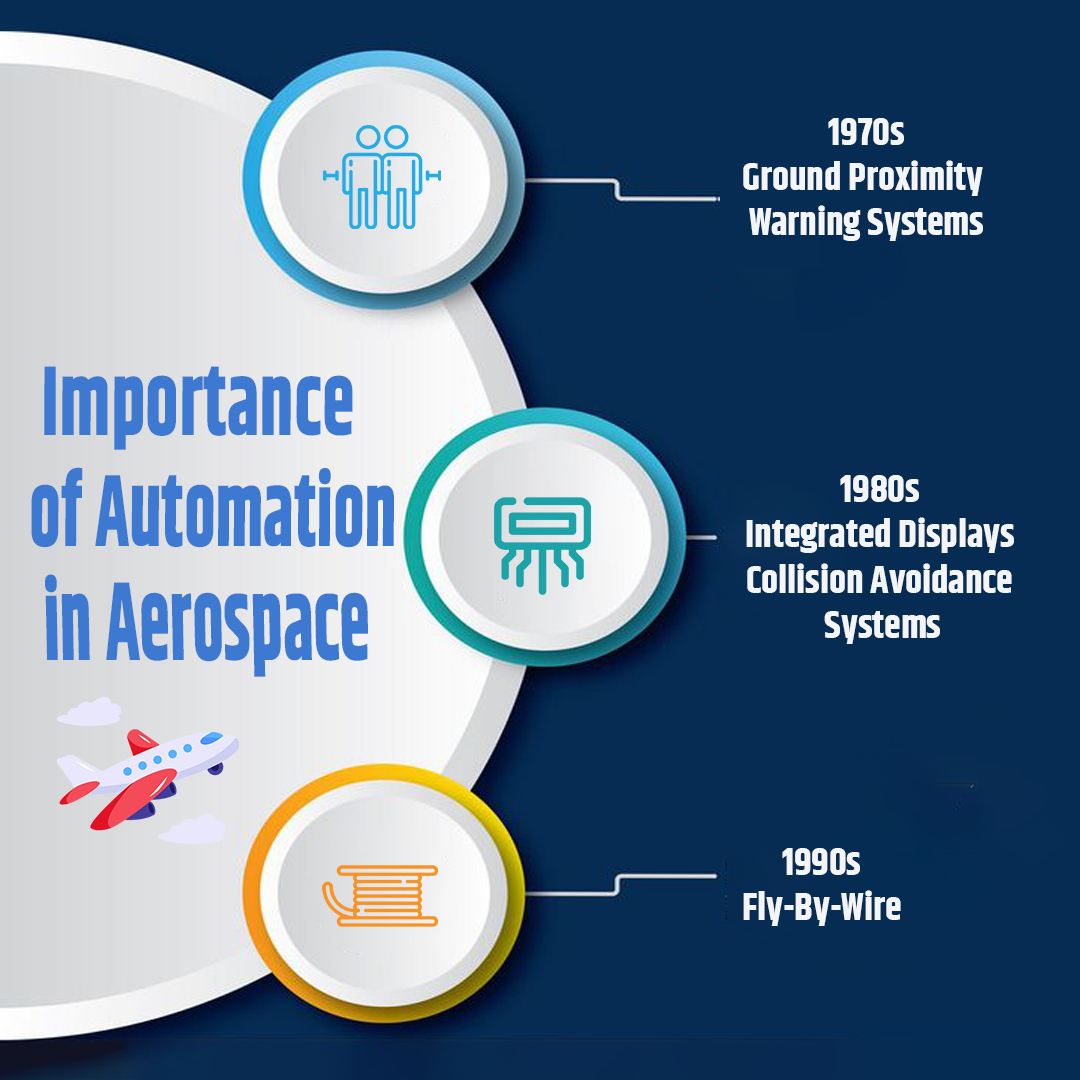

Importance of Automation in Aerospace

One of the key components of smart manufacturing is automation. This refers to the implementation of autonomous machinery and robotic systems on the manufacturing floor to automate some or all of the processes in the aerospace industry.

In addition to increasing output, automated assembly lines guarantee accuracy and uniformity while lowering the possibility of mistakes that come with manual labor.

Over the past few decades, automated systems have made significant contributions to aviation, some of which are listed here

Ground Proximity Warning Systems: Pilots are warned if their aircraft is in imminent risk of colliding with terrain by a ground proximity warning system (GPWS). Before GPWS was installed on airplanes, hundreds of people died in a number of controlled flight into terrain (CFIT) incidents.

A warning device could have prevented many CFIT events, according to studies done at the time, which led to the development of GPWS. The FAA required the system on all big turbine and turbojet aircraft in 1974.

1980s

Integrated Displays: In the 1970s, the demand to enhance cockpit functionality was prompted by the growing amount of airspace and system complexity.

Integrated displays, which were created in tandem with early automation techniques, processed, interpreted, and presented flight and aircraft system data to decrease crew workload and increase safety. The switch to two pilots in the cockpit from three was also facilitated by integrated screens.

Collision Avoidance Systems: Pilots are given greater situational awareness by a traffic collision avoidance system (TCAS), which tracks the position and trajectory of neighboring aircraft.

The algorithm suggests a maneuver that lowers the risk of a midair collision if it recognizes the possibility of one.

1990s

Fly-By-Wire: By interpreting pilot inputs and manipulating control surfaces using electronic sensors and computers, fly-by-wire (FBW) technology enables real-time aircraft performance monitoring and the application of sophisticated control algorithms.

By preventing the aircraft from going over its acceptable operating limits in emergency scenarios, FBW systems can reduce the likelihood of stalls, spins, and other dangerous situations, improving flight safety overall.

In the upcoming years, there will be a continued increase in demand for aircraft. Aerospace manufacturing technology is still too slow and expensive to satisfy the market’s present demands, let alone its growing ones.

Even while automation has advanced and only a small percentage of the assembly process is still done by hand, it nevertheless contributes significantly to production losses.

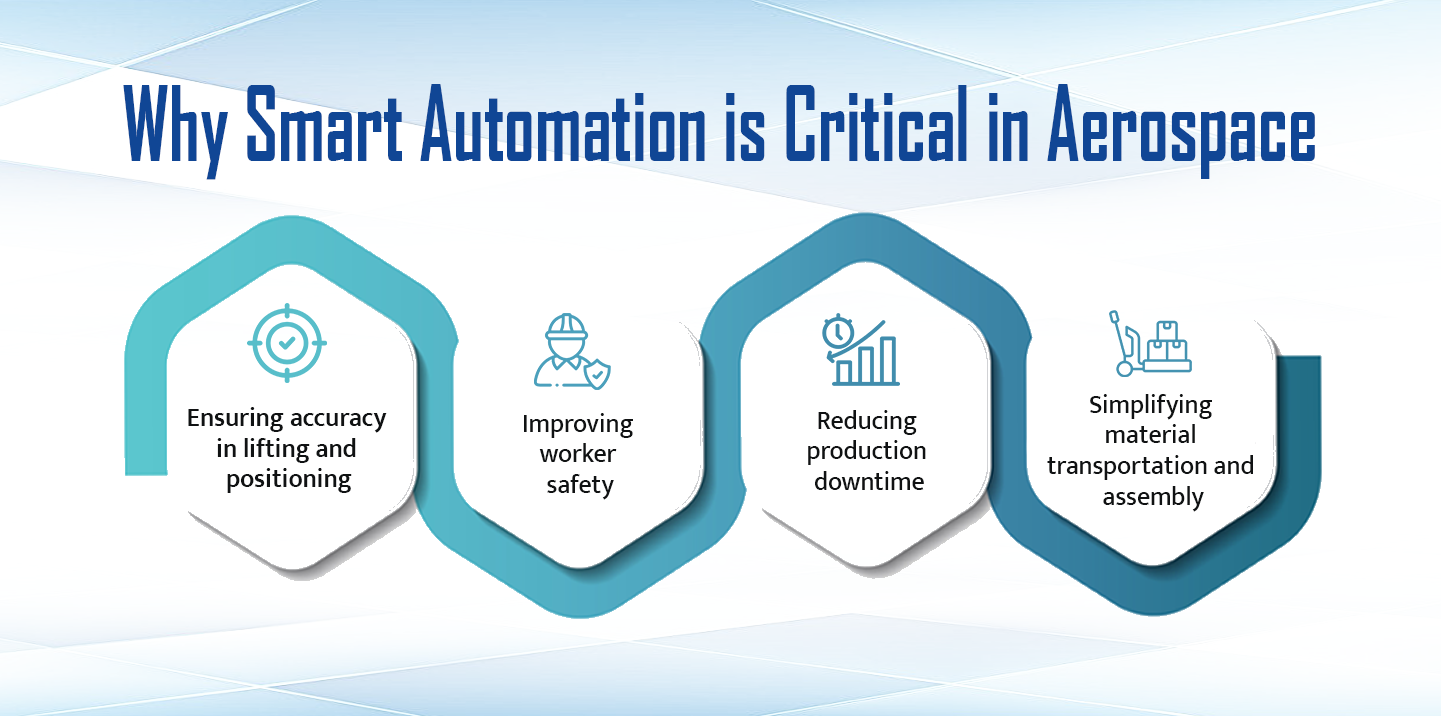

Why Smart Automation is Critical in Aerospace

Manufacturers have many significant obstacles as aerospace manufacturing increases:

- Ensuring accuracy in lifting and positioning: All aircraft parts need to adhere to exact specifications.

- Improving worker safety: Automation reduces manual handling, which increases worker safety.

- Reducing production downtime: Equipment breakdowns are avoided with predictive diagnostics.

- Simplifying material transportation and assembly: Conveyors and automated hoists increase productivity.

Aerospace businesses may improve production speeds, lower errors, and uphold stringent quality control by implementing intelligent motion control.

Key Areas of Automation in Aerospace

Manufacturing and Assembly

Robotics and automated systems are used in manufacturing and assembly to carry out precise operations like welding, riveting, and drilling. These automated technologies cut down on the amount of time needed for intricate assemblies while guaranteeing constant quality.

Quality Control and Inspection

Automated quality control systems check assemblies and parts for flaws using sophisticated imaging and sensors. These technologies guarantee that every component satisfies strict aeronautical standards by providing real-time feedback and data.

Maintenance and Repair

Predictive maintenance systems, which employ AI and IoT to track the state of aircraft components, are an example of automation in maintenance and repair. This makes preventative maintenance possible, cutting down on downtime and averting expensive malfunctions.

Supply Chain Management

Materials and parts distribution, tracking, and procurement are all made easier by automated supply chain management systems. This minimizes delays and boosts overall efficiency by guaranteeing that the appropriate parts are available when needed.

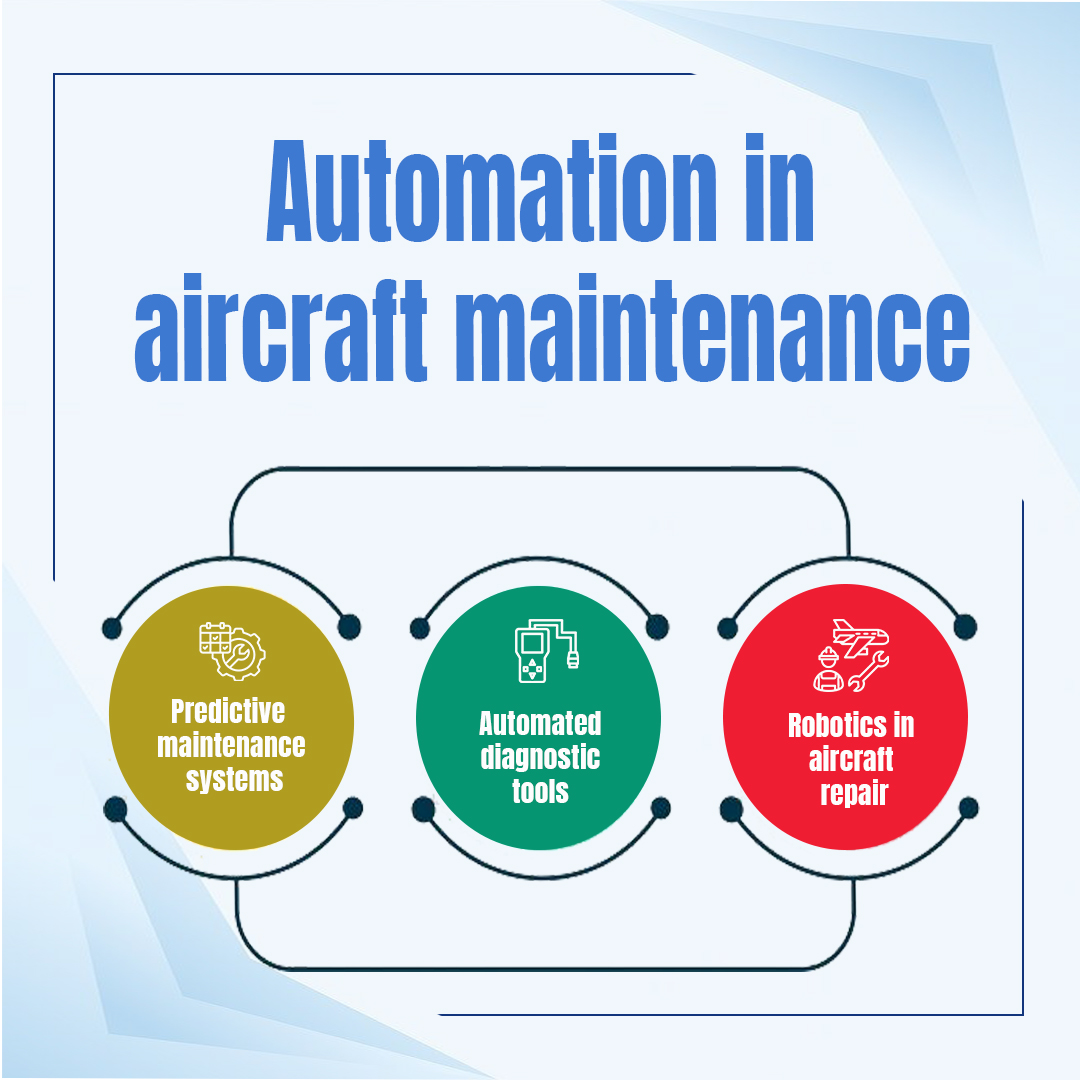

Automation in aircraft maintenance

Predictive maintenance systems: Being proactive prevents issues before they arise. Reactiveness is one thing. That is the function of maintenance systems. These artificial intelligence (AI)-driven systems analyze sensor and other data to predict component failure, enabling proactive maintenance and avoiding expensive downtime.

Automated diagnostic tools: Automated diagnostic tools make troubleshooting easier by utilizing AI and machine learning to swiftly identify issues and suggest fixes. Planes return to the air more quickly as a result of the significant time and resource savings.

Robotics in aircraft repair: Robots are assisting end effectors in aviation repair by performing intricate tasks, including applying sealant, cleaning engine parts, and checking difficult-to-reach locations. Although interventions are frequently necessary for final inspection and approval, this expedites repairs and minimizes human participation.

The Role of Robotics in Aerospace Automation

Automation in the aerospace industry is being revolutionized by robotic integration. Parts assembly, painting, and final product inspection are all done by robots.

Manufacturers can work with great accuracy, consistency, and precision when using robotic arms to drill holes or fasten components.

These robots’ sophisticated vision systems enable them to swiftly identify and locate components, guaranteeing that everything lines up precisely during assembly.

Quality control is also aided by this technology advancement on the manufacturing floor since it allows for real-time inspections to identify any possible flaws early on.

End effectors, which are essentially tools that attach to robotic arms, allow these robots to be much more adaptable and perform a wider range of tasks.

End effectors are specialized tools or attachments that expand the range of activities that robots may undertake by enabling them to execute particular jobs like welding, painting, or grabbing.

Benefits of Automation in Aerospace

Enhanced Safety: Automation in aerospace greatly improves safety by reducing human error, which is the main reason for aviation mishaps. The precision and reaction time offered by sophisticated flight control systems and autonomous features are superior to those of humans.

Increased Efficiency: Operations are streamlined via automation, which lowers the time and resources needed for different tasks. Both manufacturing procedures and flying operations benefit from this efficiency, which eventually lowers costs and boosts performance.

Innovation and Exploration: Aerospace exploration now has more opportunities thanks to automation. Scientists may now investigate far-off planets and celestial bodies with previously unheard-of precision and autonomy thanks to autonomous vehicles like space probes and rovers.

Conclusion

The aircraft sector is changing as a result of automation, which lowers costs and improves safety while increasing production, efficiency, and precision.

To spur innovation and establish new benchmarks, top aerospace businesses are utilizing cutting-edge technologies like robots, artificial intelligence, the Internet of Things, additive manufacturing, and augmented reality and virtual reality.

Automation’s influence on aerospace will only increase as these technologies develop further, influencing the sector’s future.